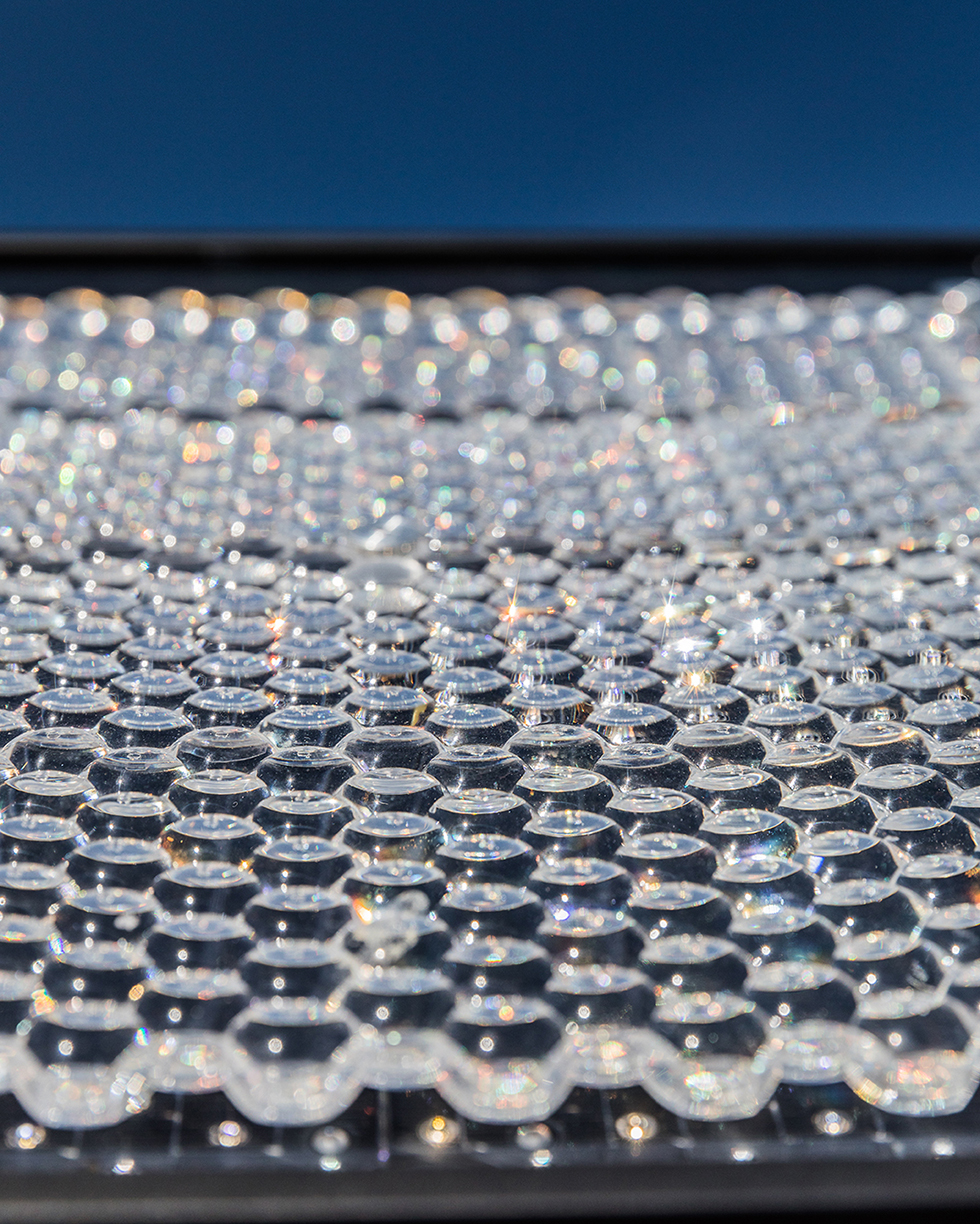

Focus on WP2: Hybrid module design optimisation for performance, costs and reliability

HIPERION Newsletter N°1 / March 2020

The goal of WP2, “Hybrid module design optimisation for performance, costs and reliability”, is to improve upon the initial design to make it compatible with mass manufacturing. The though process therefore started with the manufacturing process in mind, rather than the specific design of each component. This has been possible thanks to the close collaboration with several partners of the project. The industrial background of HIPERION partners are key to the success of HIPERION.

Throughout the first 6 months of the project a lot of input has been gathered. Careful attention has been put into making sure not to alienate the overall architecture of the module while still improving its design to facilitate the automated assembly.

Within HIPERION, two design phases are planned. GEN0 to GEN1 and GEN1 to GEN2. The first phase has now been completed and GEN1’s design is frozen. The assembly of the first GEN1 modules is planned in a couple of weeks [April 2020]. A lot of feedback will come from the manufacturing of the first modules. Furthermore, these first modules will be tested for performance and reliability. UPM and Fraunhofer ISE will carry these measurements out. Their feedback will be key to making sure GEN2’s design will be optimal.

We are looking forward to this summer, to being able to gather all this input, and put the final touches on the GEN2’s design.

By Florian Gerlich, Hiperion WP2 Leader, COO & Co-Founder of Insolight